- +91-000-000-0000

- mail@fluidynesystems.com

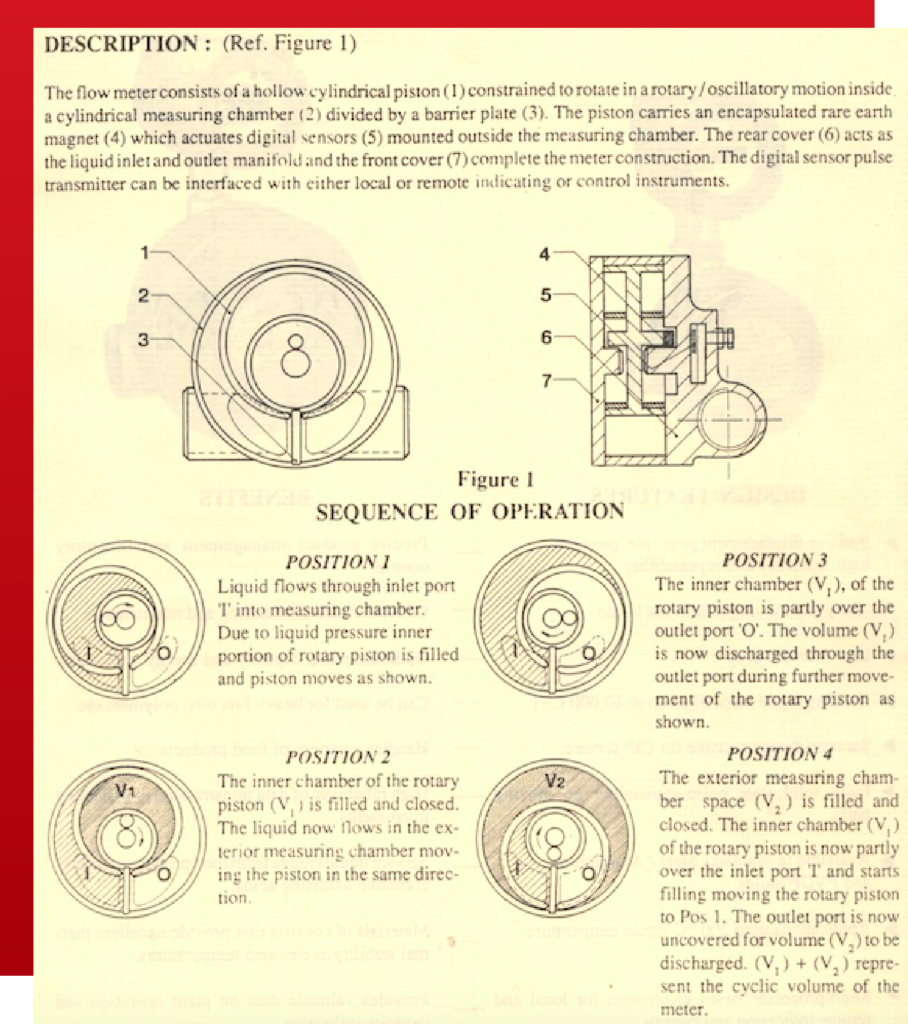

Positive Displacement Flowmeters

With a wide range of sizes in the Positive Displacement flowmeters, Fluidyne has

distinguished itself in the time-tested Oscillating Piston technology. The oscillating piston

flowmeter is the only mechanism of Positive Displacement which uses a single moving part

to achieve highest accuracy and lowest pressure drop.

Due to this the Fluidyne meters require little to no maintenance in their lifetimes and stand

out as an every-liquid solution against other inaccurate measurement techniques.

Whether it is measuring quantity of liquid in a pipe, consumption of diesel engines,

unloading fuel or chemical road tankers, batching of liquids in reactors, Fluidyne’s positive displacement flowmeters provide superlative performance. Every instrument manufactured under the Fluidyne banner carries a guarantee for quality flow measurement.

Why choose PD meters over Coriolis, Turbine, DP and VA flowmeters?

Because PD is the only principle that directly measures volume by segmenting the flow stream into discrete packets in every cycle of the moving part.

In Fluidyne’s revolutionary oscillating piston mechanism, the piston displaces a calibrated portion of liquid through its cyclic volume and a high-speed electronic counter which totalizes these packets into the total volume of liquid.

Specifications

- Accuracy – ±0.1% of measured volume. Optional – ±0.05%

- Repeatability – Better than 0.02%

- Pressure Drop – 0.1 bar

- Turndown – 1:50 (Standard), 1:100 optional

- Operating Temperature Range – -50 deg C to 150 deg C

- Materials – Aluminium LM04/ 316L/Alloy 20/ Alloy C276

- Piston – PEEK/PVDF/Ryton

- Outputs – Modbus, 4-20 mA, Pulse Output, Digital Input/Output

- Approvals –

- Ex-d IIC (ATEX)

- PESO

- Legal Metrology

- Ingress Protection

Your Benefits

- Get the best accuracy of flow measurement with the lowest pressure drop in a

Positive Displacement flowmeter - Realise the advantage of large turndown ratio in challenging applications

- Entrained air management with 100% vapor separator

- Lower maintenance due to single moving part, bearing-less design

- No change in accuracy due to varying density of product

- Alarms with fault detection features available

- Built-in protection of 100 micron strainer